PRODUCT

Sodium CarboxyMethyl Cellulose (CMC)

Carboxy Methyl Cellulose(CMC) is also named as Sodium Carboxy Methyl Cellulose CAS:9004-32-4

1)Brief Introduction

Sodium Carboxy Methyl Cellulose (CMC) is anionic cellulose ether made from cotton fiber by alkalization, etherification, purification, drying, grinding or granulation. It has the appearance of white powder or granules and the colloid solution has functions like thickening, stabilizing, emulsifying, suspending, filmforming etc. CMC is widely used in food, toothpaste, paper making, ceramics, printing and dyeing, oil drilling and other industries

2)Application

Food Grade CMC

CMC has benefits like good acid resistance, salt tolerance, high transparency, less free cellulose and gel particles, fast dissolution and good fluidity.

①. CMC can prevent the protein in yoghurt from coagulating and delamination.

② CMC can make water, fat and protein well mixed, dispersed and emulsified in ice cream, avoid ice crystals, improve taste and keep uniformity of final products.

③CMC can ensure the stability of acid drinks and extend its shelf life due to its good degree of substitution.

④CMC itself has no calorific value and is a good choice for manufacturing low-calorie foods.

Toothpaste Grade CMC

CMC is applicable to the toothpaste industry. As the most important raw material for toothpaste manufacturing, it mainly plays a role in shape forming, pasting and molding, and gives toothpaste appropriate viscosity as well as certain glossiness and delicacy.

①Good compatibility with various raw materials in toothpaste to prevent the separation of friction agent.

②Make paste delicate, water-free, shell free and thick, extend the shelf life.

③CMC has high transmittance, better rheological and thixotropic properties after dissolution

Papermaking Grade CMC

CMC is applied to the preparation of coating paper in papermaking industry, used as wet end additives and surface sizing agent etc.

①Control and adjust the rheology of paint and the dispersion of pigment.

②Good film-forming property and improve the glossiness of the coating.

③Improve the retention rate of whitening agent in the coating and improve the whiteness of the paper.

Ceramic Grade CMC

①The excellent dispersion and protective colloid properties make the glaze slurry stable without stratification.

②Adjust the viscosity of glaze slurry to make it have good rheological property and easy to glaze.

③Uniform degree of substitution, less gel particles, no insoluble matter and less residue on sieve

Oil-drilling Grade CMC

Detergent Grade CMC

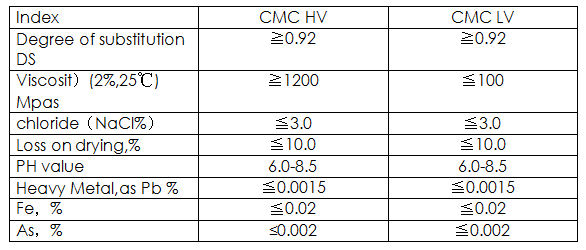

3)Technical specifications

Packaging:CMC Product is packed in three layer paper bag with inner polyethylene bag reinforced , net weight is 25kg per bag.

Storage:Keep it in cool dry warehouse,away from moisture, sun,fire,rain.

Previous: Hydroxypropyl Methyl Cellulose (HPMC)